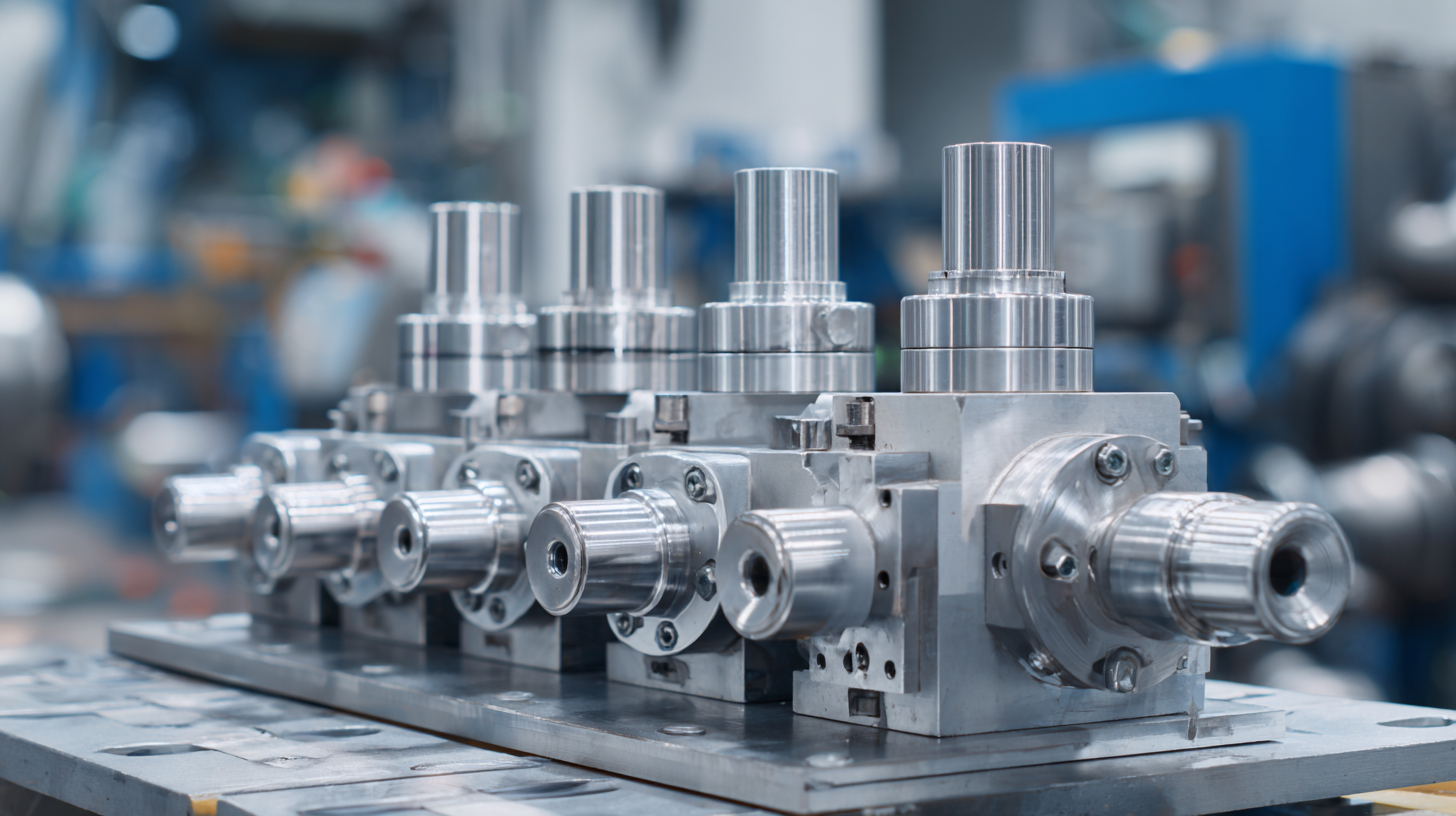

In today’s industrial landscape, the importance of selecting the right components cannot be overstated, particularly when it comes to

High Pressure Check Valves. According to a recent market analysis by Research and Markets,

the global check valve market is expected to reach USD 9.79 billion by 2027, driven by the increasing

demand for safe and efficient fluid control systems across various sectors, including oil and gas, water treatment, and power generation.

High Pressure Check Valves play a crucial role in preventing backflow and ensuring the optimal

operation of high-pressure systems, which is vital for maintaining productivity and safety. As businesses seek to enhance their operational

efficiency and minimize risks, understanding the critical attributes and sourcing strategies for these valves becomes paramount.

This guide aims to equip you with essential tips and insights to help you source the best

High Pressure Check Valves tailored to your specific business needs.

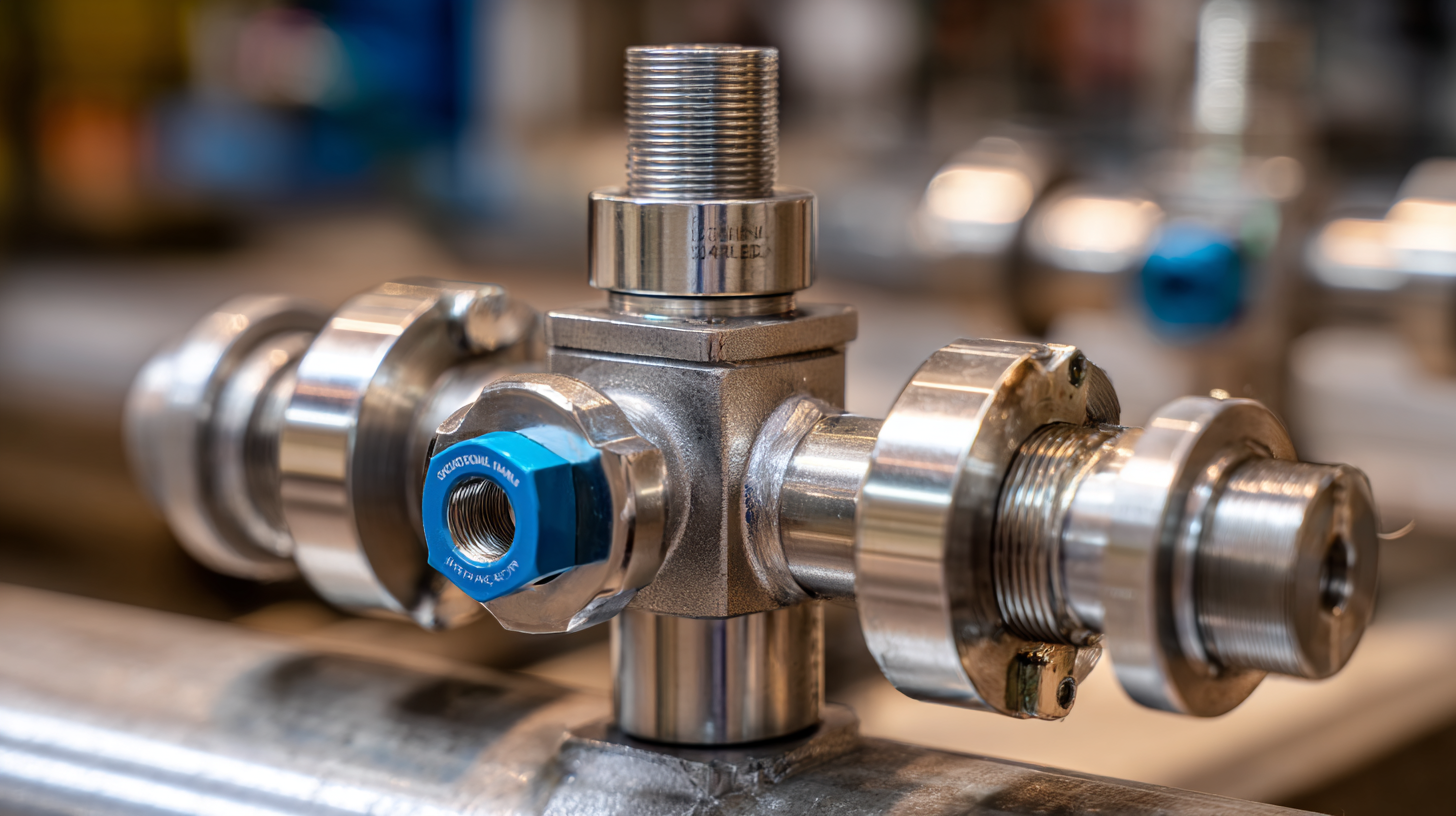

When selecting a high pressure check valve for your business, it’s essential to focus on specific key specifications that can influence the overall performance and reliability of the valve. Start by evaluating the pressure rating, as it dictates the maximum pressure the valve can safely handle, which is critical in high-pressure applications. Additionally, consider the material of the valve body.

Materials such as brass, stainless steel, or plastic can affect not only durability and corrosion resistance but also the valve's compatibility with the fluids it will regulate.

Another important aspect to look at is the valve's size and connection type. Ensuring that the valve fits correctly within your system without the risk of leaks will streamline operations and improve safety. You should also examine flow characteristics; a valve with low flow resistance will enhance system efficiency.

Lastly, don’t overlook any certifications or industry standards that the valve meets, as these ensure that the valve adheres to necessary safety and quality specifications for your specific application. By focusing on these factors, you can confidently choose the best high pressure check valve tailored to your business needs.

When sourcing high pressure check valves, a critical consideration is the balance between cost and quality. Businesses often face the dilemma of choosing between more affordable options and investing in higher quality products. While cheaper valves may offer initial savings, they can lead to increased maintenance costs, frequent replacements, and operational inefficiencies. Therefore, understanding the long-term implications of valve quality is essential for making informed purchasing decisions.

When sourcing high pressure check valves, a critical consideration is the balance between cost and quality. Businesses often face the dilemma of choosing between more affordable options and investing in higher quality products. While cheaper valves may offer initial savings, they can lead to increased maintenance costs, frequent replacements, and operational inefficiencies. Therefore, understanding the long-term implications of valve quality is essential for making informed purchasing decisions.