2025 Top 5 Bleed Valves: Best Options for Industrial Applications and Performance

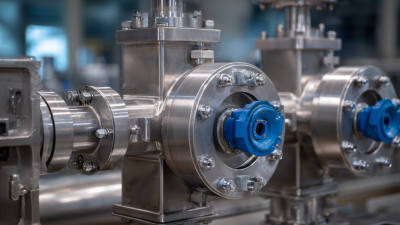

In the realm of industrial applications, the choice of valves is critical to ensuring seamless operations and optimal performance. Among the various types of valves, the Bleed Valve plays a pivotal role in controlling pressure and releasing excess fluid or gas. According to a recent report by MarketsandMarkets, the global industrial valve market is projected to reach $85 billion by 2025, with the demand for specialized valves like Bleed Valves driving significant growth. This is primarily due to their essential function in pipeline maintenance and safety management, particularly in high-pressure environments.

As industries increasingly prioritize efficiency and safety, understanding the performance characteristics and applications of different Bleed Valves becomes crucial. The diverse range of materials and designs available allows for tailored solutions to meet specific operational requirements. Moreover, an analysis from Research and Markets highlights that advancements in materials technology and automation are set to enhance the functionality of Bleed Valves, making them indispensable in industries such as oil and gas, power generation, and chemical processing. This article explores the top five Bleed Valve options for 2025, examining their features, advantages, and suitability for various industrial applications.

Top Criteria for Selecting Bleed Valves in Industrial Settings

When selecting bleed valves for industrial applications, there are several key criteria to consider. First and foremost is the valve material. Depending on the fluid being handled, it’s crucial to choose a material that can withstand corrosion and high pressures. Common materials like stainless steel or brass are preferred for their durability and resistance to chemical reactions. Additionally, the valve size should be appropriate for the flow requirements of your system to ensure optimal performance.

Another important factor is the operating pressure and temperature ratings of the bleed valve. Industrial settings often encounter extreme conditions, so selecting a valve that can handle these variables is essential. Make sure to check the manufacturer's specifications and ensure the valve's ratings align with your operational parameters.

**Tips:** Always look for bleed valves with a proven track record in similar applications. Engage with suppliers for recommendations based on your specific needs. Routine maintenance and inspection can also prolong the life of the valve, ensuring consistent performance and reducing the risk of leaks in your system.

Comparison of Materials Used in Top Bleed Valve Options

When selecting bleed valves for industrial applications, the material composition plays a crucial role in ensuring optimal performance and longevity. Among the top options available in 2025, materials such as stainless steel, brass, and polymer composites are often highlighted for their unique properties. According to a recent report by MarketsandMarkets, the global market for industrial valves is projected to reach $90 billion by 2025, driven largely by the demand for material innovations that enhance durability and resistance to corrosion.

Stainless steel, particularly types 304 and 316, is favored for its outstanding strength and resistance to harsh environments, making it ideal for industries such as oil and gas. Meanwhile, brass valves provide excellent resistance to thread galling and are often used in lower-pressure applications like water systems. On the other hand, polymer composites are gaining traction for their lightweight and non-corrosive properties, making them suitable for chemical processing applications. The selection of material can significantly impact not only the operational efficiency but also the overall lifecycle cost of the valve, highlighting the importance of this comparative analysis in the procurement process.

2025 Top 5 Bleed Valves: Material Comparison

Performance Metrics: Flow Rate, Pressure Ratings, and Temperature Limits

When selecting bleed valves for industrial applications, performance metrics such as flow rate, pressure ratings, and temperature limits are crucial. The flow rate determines how quickly the valve can discharge pressure, making it a vital consideration for maintaining system efficiency. High-performing bleed valves typically offer adjustable flow rates to accommodate various operational needs, ensuring that systems remain stable under different conditions.

Pressure ratings are another key aspect; they indicate the maximum pressure the valve can handle without failing. Opt for bleed valves with higher pressure ratings for applications involving significant pressure fluctuations. This not only enhances safety but also ensures the longevity of the valve under demanding operating conditions. Lastly, understanding the temperature limits is essential to prevent material degradation or valve malfunction. Selection of materials that can withstand both high and low temperatures will ensure the reliability and durability of the valve in diverse industrial environments.

Innovative Technologies Enhancing Bleed Valve Efficiency in 2025

In the realm of industrial applications, bleed valves play a critical role in managing fluid dynamics and ensuring system safety. The year 2025 is set to witness a remarkable evolution in bleed valve technologies, with innovations designed to enhance efficiency and reliability. Advanced materials, such as corrosion-resistant composites, are being employed to improve durability and reduce maintenance costs. Moreover, smart bleed valves equipped with IoT capabilities allow for real-time monitoring and remote control, significantly increasing their operational effectiveness in complex industrial environments.

In addition to material advancements, automation is transforming the functionality of bleed valves. Sophisticated control systems enable precise adjustments in response to fluctuating pressure and temperature conditions, optimizing performance and energy consumption. The integration of machine learning algorithms further refines predictive maintenance schedules, ensuring that wear and tear are addressed proactively. As these innovative technologies combine, the bleed valves of 2025 will not only enhance operational efficiency but also provide industries with a more sustainable and cost-effective solution for managing fluid systems.

2025 Top 5 Bleed Valves: Best Options for Industrial Applications and Performance

| Model |

Size (inches) |

Material |

Max Pressure (psi) |

Temperature Range (°F) |

Efficiency Rating |

| BV-100 |

1.5 |

Stainless Steel |

1500 |

-20 to 400 |

A+ |

| BV-200 |

2.0 |

Alloy |

2000 |

-10 to 450 |

A |

| BV-300 |

2.5 |

Bronze |

1800 |

-15 to 500 |

A- |

| BV-400 |

3.0 |

PVC |

1200 |

0 to 300 |

B+ |

| BV-500 |

4.0 |

Carbon Steel |

2500 |

-40 to 600 |

A++ |

Market Trends: Leading Manufacturers and Their Best-Selling Bleed Valves

The global bleed valves market is witnessing significant growth, driven by the increasing demand for efficient control of fluid flow in industrial applications. In 2024, the market for acid gas valves is expected to reach $98.3 million, with a forecasted rise to $147.09 million by 2032, reflecting a compound annual growth rate (CAGR) of 5.1%. This trend illustrates the critical role that bleed valves play in industrial hydraulics, particularly as industries aim for optimized performance and safety in their operations.

Tips: When choosing bleed valves for your applications, consider factors such as the material compatibility, pressure ratings, and the specific fluid types being handled. Leveraging high-quality valves can enhance not only the efficiency of your systems but also their longevity and reliability.

The industrial hydraulic equipment market is also on the rise, projected to grow from $26.13 billion in 2023 to $35.92 billion by 2030, marking a CAGR of 4.7%. Leading manufacturers are continuously innovating to meet the evolving needs of the sector, offering advanced solutions that cater to various applications. Engaging with reputable suppliers can ensure that you have access to the latest technologies and best-selling products tailored for optimal performance.