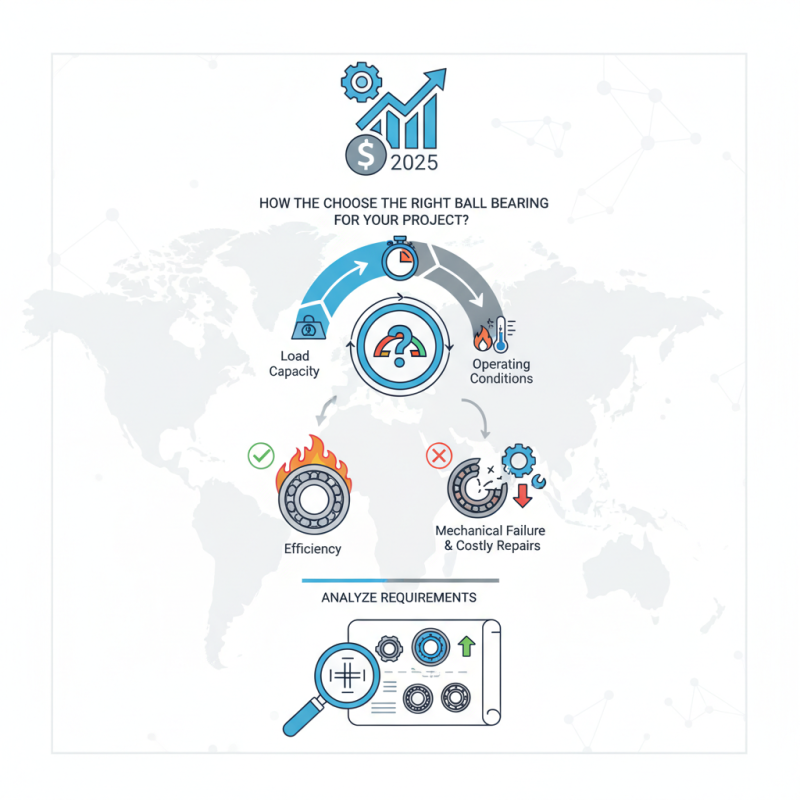

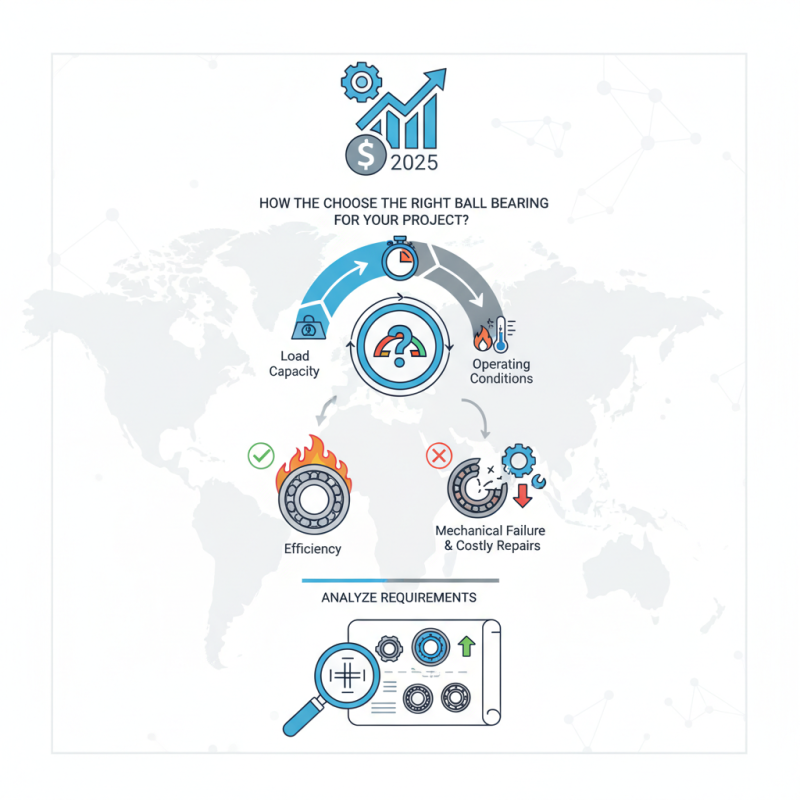

How to Choose the Right Ball Bearing for Your Project?

Choosing the right Ball Bearing is crucial for any engineering project. Ball bearings play a significant role in reducing friction and wear in mechanical systems. A recent industry report revealed that the global ball bearing market is projected to reach over $103 billion by 2025. This growth emphasizes the importance of selecting the right type for various applications.

Each project may require different specifications, such as load capacity, speed rating, and operating conditions. For example, ceramic ball bearings can handle higher speeds and temperatures. However, they may not be suitable for all environments. A poorly chosen bearing can lead to mechanical failure and costly repairs.

Understanding the specific needs of your project is key. Some might overlook these details, leading to efficiency losses. Not all ball bearings are created equal, and the consequences of a bad choice can be severe. Therefore, take the time to analyze your requirements carefully before making this critical decision.

Understanding the Different Types of Ball Bearings Available

When choosing a ball bearing for your project, it's essential to understand the various types available. Ball bearings come in several configurations, including deep groove, angular contact, and self-aligning types. Each type serves a unique purpose and has distinct features that impact their performance. According to a recent industry report, deep groove bearings account for about 40% of the market due to their versatility and ability to handle radial and axial loads simultaneously.

Deep groove bearings excel in applications requiring high-speed operation and minimal friction. They are commonly used in electric motors and automotive components. Angular contact bearings, on the other hand, support higher axial loads and are often employed in high-performance systems, such as aerospace equipment. However, they require precise installation and alignment, which can be tricky. According to data, around 25% of premature bearing failures result from misalignment during installation.

Self-aligning ball bearings offer additional flexibility, accommodating shaft misalignment. They are ideal for applications experiencing high loads. The challenge here lies in their complexity, leading to potential issues if not installed correctly. Understanding these nuances and the specific demands of your project is vital for successful bearing selection. Consider these factors carefully, as a wrong choice can result in costly downtime or equipment failure.

Key Factors to Consider When Selecting a Ball Bearing

Choosing the right ball bearing can significantly impact project performance. It's essential to consider factors like load capacity, speed rating, and operating environment. According to industry reports, nearly 70% of bearing failures are due to improper selection. Thus, understanding each factor is crucial for success.

Load capacity is a primary consideration. Determine the static and dynamic loads your application will face. For example, ball bearings with higher load ratings are necessary for heavy machinery. Remember, overestimating your needs can lead to unnecessary costs.

Speed ratings also play a vital role. A bearing's speed limit should match your application's requirements. For high-speed applications, select bearings engineered for minimal friction.

**Tip:** Always check the manufacturer specifications. Accurate information saves time and resources.

Environment affects material choice. For corrosive conditions, stainless steel options provide durability. Choosing the wrong material can lead to premature failures and costly replacements. **Tip:** Consult industry standards for environmental conditions.

Reflection on these factors ensures the right ball bearing choice for your project. Keeping these details in mind will ultimately lead to a more efficient and reliable performance.

Determining Load Capacity and Size Requirements

When selecting a ball bearing, understanding load capacity is crucial. The load capacity indicates how much weight the bearing can handle. Failure to choose the correct capacity can lead to operational issues. According to industry reports, improper load capacity can reduce bearing life by 30% or more. This underlines the importance of accurate calculations.

Size also plays a significant role. Bearing dimensions must match your design specifications. A mismatch can lead to increased friction and heat build-up. Such conditions can shorten the bearing's lifespan. A study showed that 20% of bearing failures are due to incorrect sizing. This fact highlights the need for diligent measurements in your project.

Consider the environment too. Temperature, humidity, and contaminants can affect performance. A bearing exposed to harsh conditions may require specialized materials. Many experts recommend a thorough assessment of both load and size before finalizing your choice. Balancing these factors can greatly improve reliability, though it may take some time to perfect your selection process.

Evaluating Material and Environmental Considerations

When selecting the right ball bearing, evaluating material and environmental factors is crucial. Different projects require different materials. For example, stainless steel bearings are great for corrosion resistance. However, they may not be ideal in high-temperature environments. Opting for materials like ceramic can enhance durability and performance but might be costlier.

Environmental conditions can influence your choice significantly. If your project involves exposure to moisture or chemicals, consider bearings designed for such conditions. Also, think about lubrication. Some materials require more frequent maintenance, which can complicate your project. The wrong choice could lead to premature failure or increased friction.

It's worth reflecting on these choices. Sometimes, the most apparent option may not be the best. Focus on application-specific needs rather than just material cost. Don't overlook the importance of environment; it can dictate bearing longevity and functionality. Balancing these factors may feel overwhelming, but careful consideration leads to better outcomes.

How to Choose the Right Ball Bearing for Your Project? - Evaluating Material and Environmental Considerations

| Bearing Type | Material | Temperature Range (°C) | Corrosion Resistance | Load Capacity (N) | Environmental Suitability |

| Deep Groove Ball Bearing | Steel | -20 to +120 | Moderate | 1000 | General Use |

| Angular Contact Ball Bearing | Stainless Steel | -40 to +150 | High | 2000 | Food Processing, Medical |

| Self-Aligning Ball Bearing | Brass | -30 to +100 | Moderate | 1500 | Industrial Machinery |

| Insert Ball Bearing | Composite | -20 to +60 | Low | 500 | Light Duty Applications |

| Thrust Ball Bearing | Carbon Steel | 0 to +80 | Low | 1200 | Static Applications |

Assessing Cost and Quality: Balancing Budget with Performance

When assessing cost and quality in ball bearings, it's essential to strike a balance. Poor quality can lead to equipment failure, while overspending can strain your budget. Research shows that low-quality bearings can result in a 20-30% decrease in performance. To maximize value, consider both short-term costs and long-term benefits.

Many professionals recommend analyzing your project's specific needs. For example, a high-speed application may require premium materials. Conversely, less demanding environments might allow for cheaper options. Performance metrics, like load capacity and operating temperature range, are crucial. Select bearings that meet these specifications without going overboard on price.

Tip: Always request performance data from suppliers. This allows for informed comparisons. Look for independent testing results whenever possible. Also, involve your team in decisions. Different perspectives can uncover overlooked aspects of quality versus cost. Be aware that sometimes the cheapest option may lead to higher maintenance costs later on. Balancing budget and performance is often more an art than a science, requiring careful consideration.