How to Choose the Right High Pressure Check Valve for Your Application

In industrial applications, the selection of the appropriate components is critical for ensuring efficiency and safety, particularly when it comes to fluid control systems. High Pressure Check Valves are essential in preventing backflow in high-pressure environments, which can lead to equipment damage and operational inefficiencies. According to the latest industry reports, the global check valve market is projected to reach USD 8.89 billion by 2027, driven by the increasing demand across various sectors, including oil and gas, water treatment, and chemical processing. Understanding the various types, materials, and pressure ratings of High Pressure Check Valves is vital for engineers and procurement professionals. This guide aims to provide insights into the selection process, ensuring that the right valve is chosen to meet specific application requirements and contributes to the overall reliability and longevity of the system.

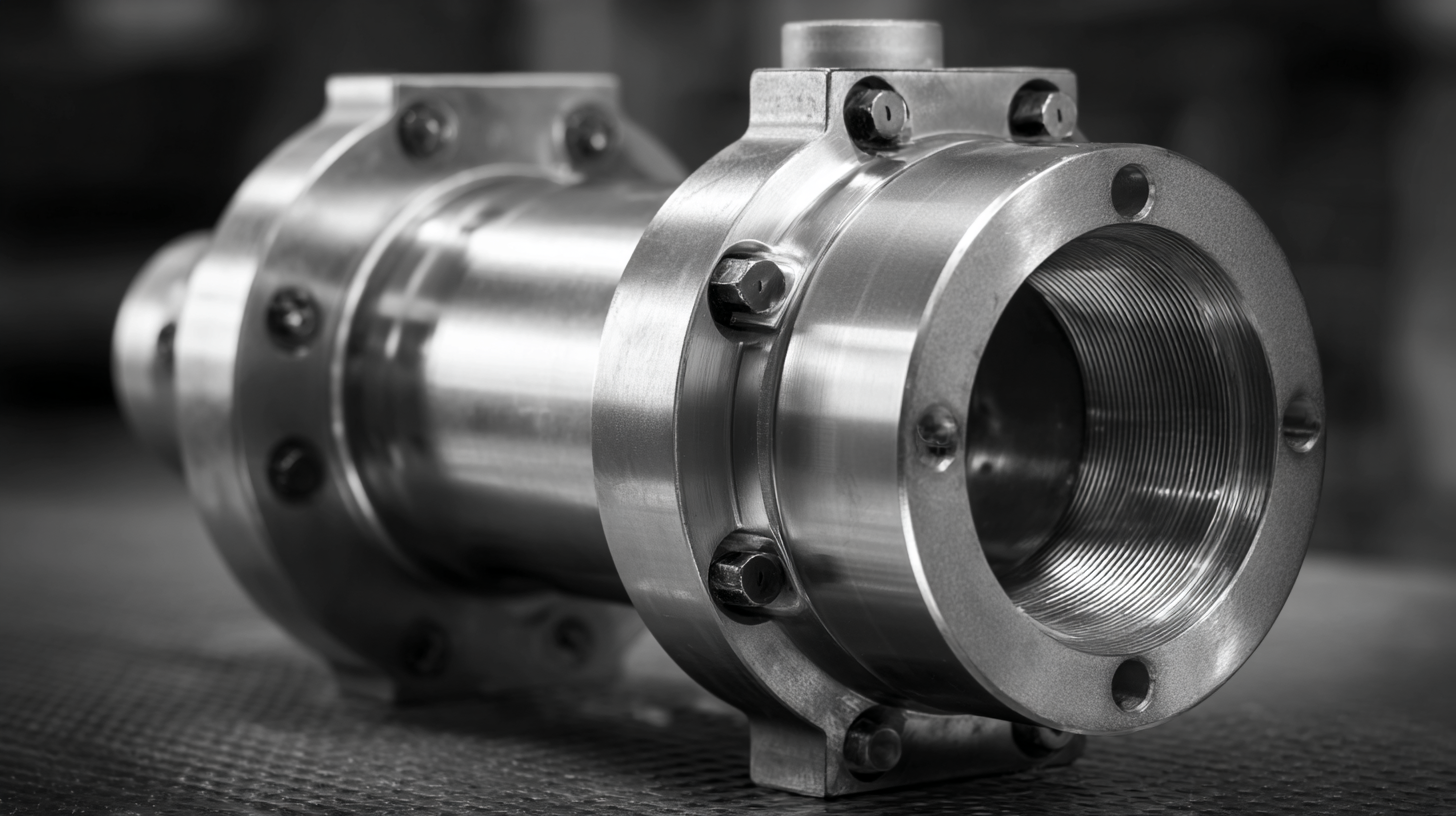

Key Factors to Consider When Selecting High Pressure Check Valves for Critical Applications

When selecting high pressure check valves for critical applications, several key factors must be considered to ensure optimal performance and reliability. The first critical aspect is the pressure and temperature ranges of the system. Check valves must be rated for the specific pressure levels and temperature extremes they will encounter to prevent failures. Understanding the operational environment enables you to choose materials that can withstand corrosive substances and prevent leakage, which is crucial in high-pressure applications.

Another important factor is the flow characteristics of the valve. Different designs, such as swing or ball check valves, influence how fluid flows through the system. It is vital to evaluate the flow rate, as well as the potential for pressure drop, to ensure the check valve can handle the required volume without compromising system efficiency. Additionally, the size and connection type need to be compatible with existing piping systems to facilitate a seamless installation and operation. Making informed choices based on these factors will enhance system integrity and longevity.

Understanding Pressure Ratings and Their Impact on Valve Performance and Safety

When selecting a high-pressure check valve, understanding pressure ratings is crucial for ensuring both performance and safety. Pressure ratings, defined by the maximum pressure a valve can withstand during operation, significantly influence its application in various industries. For instance, a valve with a rating that exceeds the operational pressure will not only enhance functional reliability but also extend the lifespan of the equipment it is integrated with. Industry reports suggest that improper selection based on pressure ratings can lead to failures, with safety incidents increasing by as much as 30% when valves operate beyond their specified limits.

Moreover, the design and functionality of safety relief valves are critical in high-stakes environments such as hydrogen dual-fuel engines and lithium-ion battery packs. As we see innovative designs emerging, such as electric-controlled pressure relief valves with rapid reaction times, the focus on making safety a top priority becomes more evident. Recent statistics indicate that over 40% of safety valve failures contribute directly to system malfunctions that can result in catastrophic events. Effective collaboration between firms dedicated to valve technology, such as recent partnerships focused on ultra-high-pressure safety relief valves, reflects the industry's commitment to improving safety measures in high-pressure applications.

High Pressure Check Valve Pressure Ratings

Material Selection: How Corrosion Resistance Influences Valve Longevity in Tough Environments

When selecting a high-pressure check valve, understanding the material's corrosion resistance is crucial, especially in demanding environments. Corrosion can significantly impact the valve's longevity and performance, leading to costly downtimes and repairs. Common materials like stainless steel, brass, and plastic each provide varying levels of resistance, depending on the specific chemicals and conditions present in your application.

Tips: Always assess the operating environment before choosing a material. For example, if your application involves corrosive substances like acids or salts, stainless steel or specialized alloys may offer the best protection. Additionally, consider the temperature and pressure conditions, as these factors can also influence material performance and lifespan.

Tips: Regular maintenance plays a vital role in valve longevity. Implementing scheduled inspections can help identify early signs of corrosion, allowing for timely interventions that extend the operational life of the valve. Investing in high-quality materials from reputable manufacturers can further enhance reliability, ensuring that your check valve stands up to the rigors of your specific application.

Flow Characteristics: Analyzing Cv Values for Optimal Efficiency in High Pressure Systems

When selecting a high pressure check valve, understanding flow characteristics is crucial to ensure optimal efficiency in your application. The Cv value, or flow coefficient, is a key parameter that indicates the capacity of the valve to allow fluid flow. A higher Cv value signifies that the valve can pass a greater volume of fluid with less pressure drop, which is essential for maintaining performance in high pressure systems. Analyzing the Cv values in relation to your system's specific requirements is the first step in choosing the right valve.

Moreover, it's important to consider how the Cv value correlates with various factors such as fluid type, temperature, and pressure variations. Different applications may demand a valve that performs well under specific conditions, so understanding the flow dynamics will help in making informed decisions. A thorough analysis of how these flow characteristics impact your system's overall efficiency can prevent unnecessary energy losses and ensure reliable operation. Thus, miscalculations in Cv values can lead to inefficient system designs, making it imperative to evaluate these factors diligently.

Maintenance and Testing Protocols to Ensure Reliability of High Pressure Check Valves

When selecting a high pressure check valve, ensuring its reliability through regular maintenance and testing is crucial. High pressure environments can lead to wear and tear, making it essential to implement a structured maintenance protocol. Regular inspections should focus on potential leaks, seat wear, and the spring's condition, as these components directly affect the valve's performance.

**Tips**: Schedule maintenance at regular intervals, ideally every three to six months, depending on the application's demands. Use appropriate lubricants and cleaning agents specific to the valve materials to avoid causing damage during maintenance.

Testing protocols should also be established to verify the valve's functionality. Pressure testing can help in identifying issues before they escalate, while functional testing checks the valve's operation under real-world conditions. Document all findings and actions taken during these tests to build a comprehensive maintenance history.

**Tips**: Implement a checklist for testing procedures and ensure all personnel are trained on how to conduct these tests effectively. Regular data analysis of test results can help in predicting failures and optimizing maintenance schedules.

How to Choose the Right High Pressure Check Valve for Your Application - Maintenance and Testing Protocols to Ensure Reliability of High Pressure Check Valves

| Parameter |

Value |

Importance |

| Nominal Diameter |

1 inch |

Determines flow capacity |

| Pressure Rating |

3000 PSI |

Ensures valve can handle system pressure |

| Media Type |

Hydraulic Oil |

Compatibility with fluid is critical |

| Temperature Rating |

-20°C to 120°C |

Prevents failure due to thermal expansion |

| Testing Frequency |

Every 6 months |

Ensures ongoing reliability |

| Maintenance Protocol |

Regular Inspection |

Identifies potential issues early |

| Installation Orientation |

Vertical |

Ensures proper flow direction |